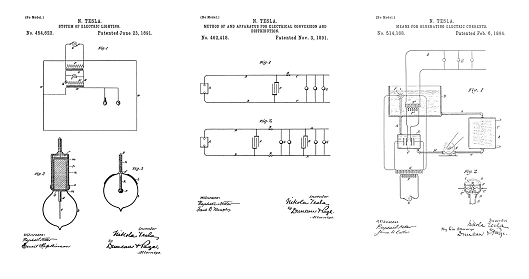

US7973296

Electromagnetic systems with double-resonant spiral coil components - Mar 5, 2009

INVENTOR: Richard T. Quick II - Publication Date: July 5, 2011

https://www.google.com/patents/US7973296

ABSTRACT

Spiral coils generate very powerful electromagnetic fields by operating with two different but simultaneous resonant behaviors. Quarter-wave resonance is established by adjusting the frequency (and wavelength) of a radiofrequency (RF) voltage source until the length of the spiral conductor is equal to ¼ of the wavelength of the alternating voltage. This generates an electromagnetic standing wave with at least one peak node and at least one null node. Inductive-capacitive (L/C) resonance is established by optimizing the thickness and width of the wire ribbon used to make the spiral coil. When inductance and capacitance are balanced, the current response will synchronize with the voltage input, creating in-phase behavior, minimal total impedance, and maximal power output. If two such coils are placed near each other, they will create an extremely powerful electromagnetic field between them, which can promote chemical and plasma reactions involving charged particles such as ions or plasma particles, possibly including nuclear fusion reactions.

DESCRIPTION

RELATED APPLICATION

The Applicant claims the benefit, under 35 USC 119, of provisional patent application No. 61/033,885, filed on May 5, 2008.

https://www.google.com/patents/US20100059692; Electromagnetic systems with double-resonant spiral coil components - Mar 5, 2009

FIELD OF THE INVENTION

This invention is in the field of electrical devices, and relates to electrical components and systems that can generate strong and powerful electromagnetic standing waves within an enclosed volume. The resulting strong electromagnetic fields have various uses, such as in chemistry involving ions or other charged particles, and in various types of imaging, diagnostic, and other devices.

BACKGROUND OF THE INVENTION

To understand this invention, the reader must be aware of two different types of electrical and electromagnetic phenomena that can occur in certain types of circuits. Both types of phenomena are referred to as “resonant” responses (or resonant activities, behaviors, etc.), but they have no connection or relation to each other, and they are created by completely different causes.

This invention involves the creation of certain types of electrical components that can simultaneously achieve both types of resonating behavior at a single operating frequency, which in most cases will be between 10 kilohertz (kHz, where 1 hertz is one cycle per second) and 1 megahertz (mHz). These components are exemplified herein by structures referred to as “spiral coils”, generally having the shape of a flat round disc, which can be modified to give a disc a conical or other shape if desired. Each such disc is created by shaping a single long conductor (such as a thin pipe, wire, or flat ribbon, made of a metal such as copper, covered by an insulating layer) into a geometric shape called an “Archimedes spiral”. This type of spiral is generally flat and disc-shaped (also referred to as having a pancake shape), which distinguishes this class of spiral from other types of three-dimensional spirals that are not flat (such as screw threads and helixes, also spelled helices).

The next two sections describe the two different types of “resonant” behavior in electric circuits. These sections are prior art, and they are well-known to physicists and electrical engineers, who are invited to skip these sections, which are included herein for the benefit of business managers, attorneys, and others who have not studied these fields of electronics, electrical engineering, and physics.

“Quarter-Wave” Resonance; Standing Electromagnetic Waves

One of the two main types is electrical resonance is referred to herein as quarter-wave resonance. This type of resonance depends almost entirely on the length of a wire element. For reasons described below, if a segment or length of wire is ¼ as long as the “voltage waves” that are traveling through the wire, then a set of “reflected” waves will be added to the emitted waves, in a synchronized alignment that creates stronger “superimposed waves”.

Accordingly, an understanding of the “quarter-wave” phenomenon will help a reader understand how a straightforward and easily-controlled factor (i.e., the length of a wire ribbon that will be used to form a spiral coil) can help create a “quarter-wave” resonant response, which will create the types of electromagnetic pulses and fields referred to as “standing waves”.

The speed at which a voltage impulse is transmitted through a metal wire is extremely fast. It is essentially the same as the speed of light, which travels 300 million meters (186,000 miles) in a single second (that distance would circle the earth more than 7 times).

If wavelength (in meters) is multiplied by frequency (cycles per second), the result will be the speed of light, 300 million meters/second. Therefore, the wavelength of an “alternating current” (AC) voltage, at some particular frequency, will be the speed of light, divided by that frequency.

Therefore, using simple division, if an alternating voltage operates at a frequency of 1 megahertz (Mhz), which is a million cycles per second, then the “wavelength” at that frequency will be 300 meters. If the frequency drops by half, to 500 kilohertz, the wavelength becomes twice as long (600 meters); and, in the other direction, if the frequency increases to 2 megahertz, the wavelength drops to 150 meters.

It should be noted that the term “cycles” is what scientists call “a dimensionless unit”, which drops out and becomes silent when other physical terms are multiplied or divided.

At AC frequencies of 10 kilohertz or greater, the common references to “alternating current” (AC) voltage begin using a different term, which is “radiofrequency” (RF) voltage. Accordingly, RF voltage is a form (or subset) of AC voltage, which operates at frequencies higher than 10 kilohertz. RF power generators are readily available, and are sold by numerous companies that can be easily located by an Internet search, using the term “RF power generator”. For example, Hotek Technologies Inc. (hotektech.com) sells two RF power generators, called the AG 1024 and AG 1012 models, which can provide output power at frequencies ranging from 20 kHz to 1 MHz; the 1012 model has a power output of 1000 watts, while the 1024 model has a power output of 2000 watts. The output frequency of any such RF power supply can be adjusted and “tuned” across the entire range of operating frequencies, merely by turning knobs or manipulating other controls in a power supply of this type.

In a wire having a fixed and unchanging length, the easiest way to create a “standing wave” is to adjust the RF frequency emitted by a power supply with an adjustable frequency, until the “tuned” frequency creates a wavelength that is 4 times as long as the wire. This principle is well-known to physicists, and it is commonly referred to as “quarter-wave” behavior, since the length of the wire segment must be ¼ as long as the wavelength. Since it is important to this invention, the principles behind it are illustrated in a series of drawings provided in FIGS. 1-4, all of which are well-known prior art.

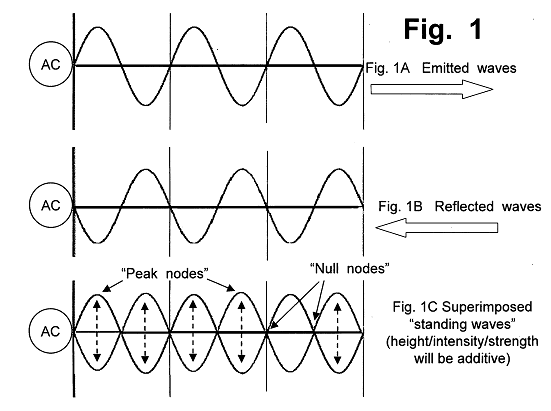

FIG. 1A indicates an idealized wavelength of an alternating voltage, depicted by a sine wave that is being sent from an AC power supply (shown by a circle at the left end of a horizontal straight wire) into the “input” end of the wire. The voltage waves travel through the wire toward the right, as indicated by the block arrow in FIG. 1A. When the waves reach the end of the wire, they cannot leave the wire (at least, not in a simplified and “ideal” system, which is being assumed and used herein to explain the principle of how a simple straight wire can create a standing wave). Therefore, the voltage wave will effectively “bounce” or “reflect” back from the tip of the wire, and the “reflected wave” will begin traveling back through the wire, going in the opposite direction, as indicated by the left-pointing block arrow in FIG. 1B.

Because of the laws of conservation of energy, the reflection and “return travel” of these types of waves, when they bounce off the tip of a wire, is actually quite good, and rather efficient, as discussed below, provided that the wire tip does not emit sparks, arc discharges, or other “escaping” electrical energy.

Accordingly, FIG. 1A depicts a set of “emitted waves” traveling toward the right, while FIG. 1B, aligned below FIG. 1A, depicts an idealized set of “reflected waves” traveling toward the left in the same wire.

FIG. 1C illustrates what happens when both sets of waves (emitted and reflected) are superimposed on each other. Since the two sets of waves are traveling at exactly the same speed, and since they have exactly the same wavelength, they will create a “standing wave” pattern when they are added together. As can be visualized from FIG. 1C, there will be a first set of locations, along the length of the wire, that can be referred to as “peak nodes”, where the alternating current voltage will be going through maximum fluctuations.

In a location halfway between a pair of adjacent “peak nodes”, there will be a spot that can be called a “null node”, a “zero node”, a trough or valley node, or similar terms. At each “null node” location, the alternating current voltage will appear to be not fluctuating at all. Those are the sites, along the length of the wire, where each “positive” hump (created by a sine wave traveling toward the right) will be counter-balanced and offset by a “negative hump” with the exact same height, traveling at an identical speed toward the left.

As a result, this type of response within a wire creates a “standing wave”. If the instantaneous voltage is measured at a “null node”, it would appear that nothing is happening, in terms of fluctuating voltage. Furthermore, the “null node” will not be moving, along the length of the wire; instead, it will appear to be standing still.

This can be demonstrated, in a coil, by using a “grounded lead” to test for voltages along the length of a coil. If a “grounded lead” coupled to a volt meter is used to touch the surfaces of a series of strands in a non-insulated coil (such as a coil made of thin copper tubing, wrapped around a plastic cylindrical shape, as used in the types of large transformers used by hobbyists to create “Tesla coils” that will emit large and visually impressive electrical arcs), the “test lead” will detect no apparent voltage at a null node, which will occur at some particular strand in the coil. At a different strand of the coil, the “test lead” will detect an alternating voltage that has twice the strength and intensity of the voltage being emitted by the power supply.

If voltage is measured at a “peak node”, the voltage will be doing something that can be called, using vernacular or laymen's terms, “the full-tilt boogie”. The AC voltage levels will be moving back and forth, between: (i) a very high and intense positive voltage, to (ii) an equally intense negative voltage. This is indicated by the “bubble” shapes shown along the wire in FIG. 1C.

The “bubbles” that are shown in FIG. 1C can help someone understand how standing waves are created, and how they act in a synchronized manner. However, that drawing fails to show another result which is very important in what actually happens in a standing wave. For purposes of description and analysis at this introductory level, the system can be assumed to be “ideal”, which implies a perfect “mirror-image” reflection of each wave from the right end of the wire. An “ideal” system also implies that no reflections occur at the left end of the wire where the power supply is located, and all “reflected” wave activity simply ceases. In real circuits and wires of this type, second and third order reflections do in fact occur, and they are used to further increase the strength and power output of these types of systems; however, those additional factors and “harmonics” should be ignored until after the basic principles of this type of system have been grasped and understood.

In an ideal system, when the reflected waves (which are traveling toward the left, in the wire segments illustrated in FIG. 1) are “superimposed” on the emitted waves (traveling toward the right), the “peak” positive voltage that will be instantaneously reached, at the highest point of each “bubble” shown in FIG. 1C, will occur when the positive peak of an emitted wave crosses a mirror-image positive peak of a reflected wave, traveling in the opposite direction. Accordingly, when those two “positive peak” values are added to each other, the instantaneous positive peak voltage that will occur, in the wire, will actually be twice as intense as the “positive peak” voltage being emitted by the AC power supply.

An instant later, at that exact same point on that segment of wire, a negative peak voltage will be created, which will be the sum of (i) the negative peak voltage emitted by the power supply, and (ii) the negative peak voltage of a reflected wave also will pass through, traveling toward the left. At that instant, when those two negative peak voltages are added to each other, the instantaneous negative voltage that will occur, in the wire, will be twice as intense as the “negative peak” voltage being generated by the AC power supply.

A more accurate and representative visual depiction of a “standing wave” in a wire would actually show the heights of the peaks as being twice as tall as the peaks of the emitted voltage waves, and the reflected voltage waves. However, that depiction might confuse people, so it usually is not shown in drawings of “standing waves”.

Accordingly, the instantaneous response in the wire, at a location halfway between two “null nodes”, is doing something that can fairly and properly be called “the full-tilt double double boogie”. The “double double” phrase (note that it contains not just one but two “doubles”) was added to that phrase, for two reasons:

(i) To emphasize the fact that each and every voltage peak (maximum positive, and maximum negative) will be twice as strong, and twice as intense, as the maximum positive and negative peak voltages emitted by the power supply; and,

(ii) to point out that the frequency of the superimposed “bubbles”, shown in FIG. 1C, is actually twice as fast as the frequency of the AC cycle that is emitted by the power supply, as discussed below.

The “twice the intensity” result is directly comparable to what an observer will see, if a large mirror is placed behind a light bulb in an otherwise dark room. The mirror effectively keeps the room dark, everywhere behind the mirror, so there is no “magical doubling” of the light in the room; that would violate the basic law of conservation of energy. Instead, what the mirror does is to shift light away from the backside of the mirror, and keep that light energy on the reflective side of the mirror. Anyone standing in front of the mirror will see two apparent lightbulbs. Both of those lightbulbs (the original bulb, and the reflected image) will have the same brightness (if the mirror is perfect). Therefore, the mirror will double the intensity of the light energy reaching the observer.

That same effect, in a circuit, will happen if the end of a wire acts like a mirror. If a wire does not have any components that will cause it to become an active “emission source” (which is the behavior of transmission antennas and certain other components), in a way that efficiently releases voltage-created energy into the atmosphere, then the basic rules that require conservation of energy will prevent that energy from simply disappearing and ceasing to exist. As a result, even if the end of a wire is not designed to be a perfect reflector, a large portion of the voltage wave will indeed reflect off the wire tip, and travel back through the same wire, in a “second pass”.

To adequately understand the type and amount of “wave reflection” that occurs at a wire tip, consider what happens if a light bulb is shining in a room that has shiny, glossy white paint on all the walls and ceilings; then, consider how it would look if the same light bulb were located in a room with all of the walls and ceilings painted “flat black”. The total amount of light that would be available, to carry out a task such as reading a newspaper, clearly would be much greater in the white room, because light reflects off of white paint, even though white paint does not even begin to approach the type of “reflection quality or clarity” that a mirror creates. The difference in what happens, when light intensity in a room painted flat black is compared against a room painted a glossy white, does not arise from the presence or absence of “reflection quality or clarity”; instead, it is governed by the laws of conservation of energy. When light shines onto a surface that is painted flat black, the light energy is absorbed by the paint, and it literally warms up the paint. By contrast, glossy white paint will not absorb light energy, so it reflects the light back out, for a “second pass” through the air that fills a room.

Because of the laws of conservation of energy, and without depending on any “quality of reflectance” trait that is built into wire tips, electrical energy cannot simply disappear, when it reaches the tip of a wire. Instead, only two things can happen to that energy:

(i) the electrical energy can be emitted into the surroundings, such as by emitting sparks, arcs, or radiofrequency signals that will carry energy; or

(ii) if the energy is not emitted by the tip of the wire, then, by simple necessity and because of the basic law of conservation of energy, it must be reflected back into the wire, and it will be forced to travel back through the wire again.

If a wire has a long and tapered tip, then the reflected wave might become somewhat diffused, and it might lose some portion of the “clarity” of the wave. However, since wavelengths in the frequencies of interest herein are hundreds of meters long, the type of tip created by a conventional wire cutter will not create any significant diffusion, in a reflected wave. And, unlike the white-painted walls of a room, there is not a large area that is available, at the tip of a wire, that can create scatter, spread, or diffusion. As a result, the tip of a wire will be a relatively efficient mirror-type reflector, when an AC voltage is “pumped” into one end of the wire.

The second factor mentioned above, when the “double-double” boogie phrase was mentioned, relates to a doubling of the frequency of a standing wave. When a standing wave is created in a wire by reflection of an emitted AC voltage wave, the frequency of the standing wave is, quite literally, double the frequency of the emitted wave.

This can be seen, visually, by noting that in the emitted AC voltage, shown in FIG. 1A, a single complete wavelength contains both a “positive hump” and a “negative hump”. Accordingly, three complete sine waves, divided into three segments by the imaginary vertical lines, are shown in FIG. 1A.

By contrast, each and every “bubble” shown in FIG. 1C depicts a complete and total “wavelength”, in a standing wave. Six of those standing wave “bubbles” fit into the exact same length of wire that holds only 3 emitted wavelengths from the power supply.

The “frequency doubling” effect of standing waves is important, because alternating current systems can convey and release energy in a manner that increases, as the frequency of the AC voltage supply increases. To some extent, this is analogous to saying that, if a motor can be run at twice the speed (while still generating the same torque), then the work output of that motor can be twice as great, at the twice-as-fast speed. That analogy is not entirely accurate, since work output from an electric device that uses AC power depends on “area of the curve” functions that occur when sine waves are involved. Nevertheless, as a general principle, if voltage frequency increases, then power output will also increase, in many types of electric circuit components.

Accordingly, the three panels in FIGS. 5A, 5B, and 5C depict those general principles of standing waves, in a way that can be visually understood by considering what happens in a wire with a length equal to a multiple of the voltage wavelength.

In the three panels of FIG. 1, the wire length is three times as long as the wavelength of the voltage from the power supply. However, to create standing waves, a wire length does not need to be any particular multiple of the wavelength of an AC voltage. As can be seen by considering FIG. 1C, the same types of “bubbles” would be created: (i) if the wire length were exactly twice as long as the wavelength; or, (ii) if the wire length were the same length as the wavelength.

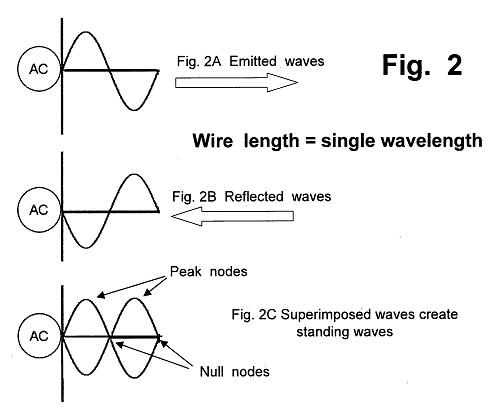

Accordingly, FIG. 2 (which includes FIG. 2A showing an emitted wave, FIG. 2B showing a reflected wave, and FIG. 2C showing the superimposed “bubbles”) shows what happens in a wire segment that has a length that is equal to a single wavelength from an AC voltage at a fixed frequency. A resonant standing wave will be formed, with a frequency that is double the frequency of the input AC voltage. That same result will apply, in a wire having any length that is an exact (integer) multiple (such as 1×, 2×, 3×, etc.) of the wavelength of the AC voltage being pushed (or forced, driven, pumped, etc.) into the wire segment.

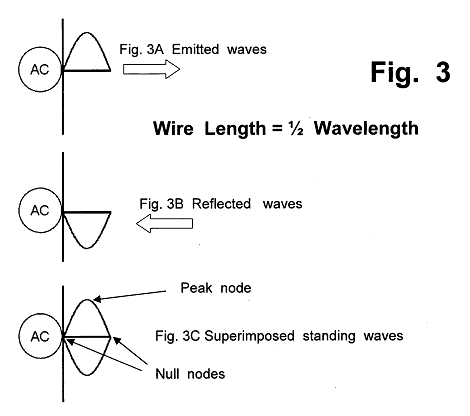

Moving to still shorter wires, the same principle also applies to any wire with a length equal to ½ of an AC voltage wavelength. As shown in FIG. 3 (which includes FIG. 3A showing an emitted wave, FIG. 3B showing a reflected wave, and FIG. 3C showing the superimposed “bubbles”), if the wire length is ½ of the wavelength, a natural and resonant standing wave will still form, with a frequency that is double the frequency of the input AC voltage.

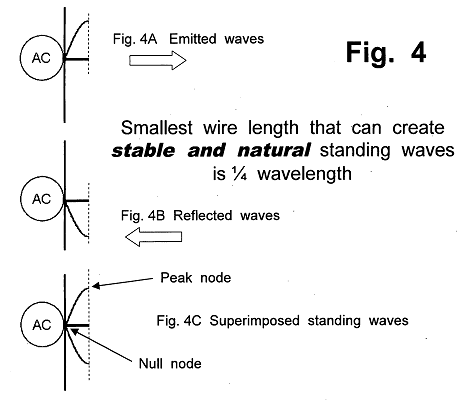

Finally, moving to a still shorter wire, the same principle also applies to any wire that has a length equal to ¼ of an AC voltage wavelength, as shown in FIGS. 4A, 4B, and 4C. Even though it does not stretch across or cover a complete “bubble”, the standing wave shown in FIG. 4C is nevertheless a stable, natural, and resonant “standing wave”, with a frequency that is exactly twice the frequency of the input AC voltage.

It can be possible to create partially stable and semi-resonant responses, using ⅛, 1/16, or shorter lengths of wire, by using additional devices that can remove electrical power from the system, or that can generate effects that are usually called “harmonics”. However, those are not the types of natural and stable responses that can be created by a simple, basic system consisting of nothing more than: (i) a wire having a fixed length and a “reflective” tip; and (ii) an AC power source with a frequency that can be “tuned” until it creates a resonant response in any wire segment having a suitable length.

Therefore, since quarter-wave wire lengths are the shortest lengths that can create natural and stable standing waves, the conventional term that is commonly used, to describe what happens when a wire creates a resonant standing-wave response, is a “quarter-wave” response.

In some devices, telescoping components (or other elements that can alter the effective length of a wire-type element) can be used to alter the ability of the element to respond to a fixed wavelength. Many types of antennas use this approach, if they need to process signals that are being transmitted on fixed and known frequencies. However, those examples are not relevant to spiral coil reactors, which will use an approach that involves tuning and adjusting the frequency of the voltage that is being supplied to a reactor, until a resonant response is observed in coils with fixed and unchanging lengths.

It should also be noted that certain types of “tuning” elements (such as capacitors, which can have either fixed or adjustable capacitance levels) also can be electrically coupled to a wire, in a manner that “emulates” adding more length to a wire. This approach can be used to alter (or increase the range of) the frequencies that a wire circuit will resonantly respond to. Capacitors and other “tuning” elements will be able to provide “tuning” capability to at least some types of spiral coil reactor discs as described herein. However, high-performance reactors designed for very high voltages and frequencies will need to have a strong, stable, and “robust” ability to resist or handle kickbacks, power surges, and other adverse events. Therefore, in “high-performance” reactors, any added tuning element or other nonessential component will create an additional opportunity and location where something might fail. As a result, any such additional elements generally should be avoided, when possible.

Accordingly, a preferred approach to designing and assembling high-performance spiral coils, for use in reactors as described herein, involves:

(i) creating two identical strong and sturdy coils that will both respond to a single “resonant frequency”, in a manner that will not require additional tuning elements; and,

(ii) using an AC power supply with a adjustable (tunable) frequency, to provide a resonant frequency that works well with both coils.

It was mentioned above that the “ideal” system that was used to describe the principles of “quarter-wave” behavior, in a wire coupled to an AC power supply, required two assumptions:

(i) completely efficient reflection of the wave, at the “mirror” end of the wire (the right end, in FIG. 1); and,

(ii) total absorption of the reflected wave, once it travels in a “second pass” back to the power supply.

In a real system, neither of those assumptions will be completely accurate. Among other things, there will be some loss and emission of power (both along the length of the wire, and at its end) which will erode the power and “peak heights” of the reflected waves; and, there will be some “reflection and bounceback” of the second-pass reflected wave, when it reaches the “entry” end, where the wire is connected to the power supply.

However, rather than undercutting or contradicting the “idealized” assumptions that can help explain how standing waves are generated by “quarter length” wires, the partial losses and partial reflections that occur in real coils actually help explain what really occurs, when resonant standing waves are formed inside a real wire.

What actually happens, inside such a wire, is that a set of third pass waves (which will reflect off of the left end of a wire segment, where the power supply is attached) will fall into either of two different conditions:

(1) If the “third pass” wave is “in phase” and aligned with a “new” set of outgoing voltage waves (fresh from the AC power supply), then those two sets of waves will work together, and will be aligned and synchronized, so that each wave enhances and strengthens the other wave. This creates a substantially more powerful wave (which can be called a “first-and-third” wave), which travels through the wire, away from the power supply (toward the right, in FIG. 1). When that stronger and more powerful “first-and-third” wave reaches the reflective right end of the wire, most of that stronger combined “first-and-third” wave will bounce back, thereby creating not just a “second pass” wave, but a “second-and-fourth pass” reflected wave, which also will be correspondingly stronger, and more powerful.

This leads to even greater and higher “superimposed” voltage peaks in the wire, and it doesn't stop there. If they are properly and perfectly synchronized with each other, then all of the “odd numbered” waves will begin to build up, higher and higher, adding to each other and traveling in synchronized harmony toward the right. Furthermore, the fact that the aggregated “odd-numbered waves” become higher and higher, leads to a corresponding increase in the height and strength of the aggregated “even-numbered waves”, which are reflecting off of the tip at the end of the wire, and traveling back through the wire toward the power supply.

That is what creates resonant “standing waves” in a wire or electric circuit that is long enough to create standing waves. If any and all of the “accumulated feedback” in a system can be smoothly and efficiently added to, coordinated with, and synchronized with an “initial output”, then that behavior, in that circuit, is classified and referred to as a “resonant response”. Anyone who has seen a resonant response peak of that type (which can be, quite literally, orders of magnitude higher than any surrounding nonresonant response levels), on an oscilloscope or similar monitor, can visually see what happens when an input frequency is adjusted so that a set of “feedback” signals begin to act in synchrony and harmony with the initial signal.

(2) In direct contrast to the above, and as the only other option out of the two possible options (i.e., they are either synchronized, or they are not synchronized), if the “feedback” signals are not synchronized and aligned with the “initial output”, then the “feedback” signals will not merely fail to boost the initial output. Instead, the feedback signals will actively interfere with the initial output, in ways that aggressively undercut its power and reduce its efficiency. The “feedback” begins acting in a manner comparable to small children who insist and demand that their father must carry them, while he is trying to run a race. They are not neutral, and they cannot be ignored; therefore, they become actively disruptive and detrimental, in a system that is struggling to work efficiently. This explains the other side of how and why a “resonant response” can be orders of magnitude higher and more powerful than non-resonant responses.

As a simple demonstration of how powerful and important “standing wave resonance” can be, consider what happens when someone uses a knob, rather than a button, to tune an old-style radio to a certain radio station. The reason that a listener can hear that particular station clearly, without also hearing static and noise from all the other radio stations in that city, is because the tuning mechanism, inside that radio, has been set to a level that creates a “resonant response” with the frequency of the selected radio station. The signals from any other station, even at the closest adjacent frequencies being used by other radio stations, are so much weaker that they can be easily filtered out, and cannot even be heard, on any decent radio tuned to a station that is broadcasting at a certain frequency. That demonstration offers an example of how focused, powerful, and effective a “resonant response” can be, compared not just to background noise, but also to nonresonant responses at “close but not exact” frequencies.

Before leaving the topic of “quarter-wave” or “standing wave” resonance, it should be noted that if an RF power generator has a frequency range up to 1 Mhz (such power supplies are common, and can be used for testing herein, which is why they are being mentioned now), the shortest wavelength they can emit reliably will be 300 meters, at 1 Mhz. That 300 meter minimum wavelength will require that a wire having a “quarter wave” length must be at least 75 meters long, to generate standing waves when that power generator is used. Since many electrical devices suffer from distortion and other problems when they operate at the outer limits of an advertised or rated operating range, the smallest and shortest coils that are of interest herein, for analyzing the types of double-resonant behavior that will create powerful standing waves, will be about 80 meters long. That wavelength corresponds to a 940 khz frequency, which can be achieved with a fair margin of safety, with minimal distortion, by nearly any power generator that is rated at a 1 Mhz maximum frequency.

This completes an overview of how the length of a wire will determine a resonant standing wave frequency, in a simple system consisting of a wire coupled to an AC power supply.

However, the length of the wire is not the only important factor that will affect how a spiral coil reactor will perform. Instead, standing wave resonance is only one of two important types of electrical resonance. A completely different type of resonance is discussed in the next section.

Inductance, Capacitance, L/C Balance, and “In-Phase” Power

Inductance (represented by the letter L) and capacitance (represented by the letter C) require close attention in designing, testing, and optimizing spiral coils that can achieve the high efficiency in generating powerful electromagnetic fields that can work in charged-particle reactors as described herein.

The three properties that physicists and electrical engineers call inductance, capacitance, and resistance are grouped together and collectively called “impedance”. Those three factors are the three main factors that can and will “impede” (i.e., hinder and reduce) the efficient flow of current, through a circuit. All three of those “impedance” factors and their effects (and the types of components that can be used to create, reduce, apply, avoid, control, and manage them) are taught in any basic course in electrical engineering, and it would be an act of incompetence for an electrical engineer to design any type of circuit without analyzing all three impedance factors, and without taking all three into account.

Briefly, inductance (represented by L) refers to the tendency of any wire coil to resist any change in current flow (or in electromagnetic field strength), as an immediate and instantaneous response to a change in the voltage that is applied to the coil. Therefore, inductance is analogous to the mechanical traits of inertia, momentum, and mass. A car cannot instantaneously change from traveling at a certain fixed speed, to traveling at a faster speed, as an instantaneous effect of some applied force. No matter how much force is applied to a car, there must be some time lag that will occur, while the car accelerates to a higher speed, in response to a higher level of force being applied to it. The needle on a car's speedometer cannot instantaneously jump from 30 miles per hour, to 50 miles per hour; instead, when a car accelerates, the needle must and will rotate through an arc that will pass across each of the intervening speeds. That is the nature of mass, momentum, and inertia.

The same principle applies to the current response in an inductor coil, when the voltage changes. If a higher voltage is applied to the coil, the coil will not and cannot respond with an immediate and instantaneous “matching” rise in current flow. Instead, any change in current will “lag behind” a voltage change.

That “lag time” becomes crucially important in “alternating current” systems, such as (for example) the 60-cycle AC power system that is used in North America. In an electric motor, or in any other device that converts electric power into actual work output, the efficiency, power rates, and actual work output of the motor or other device depend on multiplying voltage, and current. Indeed, the very definition of a “watt” (the most important and basic unit of electric power) is this: a watt is the amount of power that is being provided, and used, when 1 volt is driving 1 ampere (or amp) of current, through some type of electrical device. By simple math, a kilo-watt of power (i.e., 1000 watts) is being provided, and used, when a voltage of 100 volts drives 10 amps through an electrical device.

In a “direct current” system, it is easy to multiply a steady and unchanging voltage value, times a steady and unchanging current value. However, in an alternating current system, where the voltage follows a “sine wave” function that alternates back and forth between positive and negative values, 60 times every second, while following a rounded and sloping curve without any “square blocks”, that type of multiplication becomes much more complicated. As a result, if instantaneous peak current values are not aligned properly (in time) with peak voltage values, the system will suffer from problems that are referred to by phrases such as “out of phase” and “unsynchronized”. The system will also be referred to as having a low (or hindered, impaired, etc.) power factor.

If a motor or other device is forced to perform in an “out of phase” manner (or, stated in different but consistent terms, if the device has a low power factor), it cannot and will not perform with optimal efficiency. This would be analogous to listening to a song, where half of the instrumental and vocal tracks were laid down, in the final mixed version, a fraction of a second behind the other instrumental and vocal tracks. That kind of “mix” would sound awful, and no one would want to hear it.

“Out-of-phase” problems are common. As one example, they would occur (if not corrected) in nearly all electric motors, since the “windings” in nearly any type of electric motor will create inductance, which in turn will force the current responses (inside the motor windings) to lag behind (and be “out-of-phase” with) the voltage cycle.

Fortunately, there are ways to correct “out-of-phase” performance problems, in motors and other appliances that use coils and windings, by using controlled levels of capacitance to offset and “balance” the inductance created by the coils or windings.

In an AC circuit that operates on a regular cycling basis, capacitance will cause the current response in the circuit to “lead” (or precede, antecede, etc.) the voltage cycle. In this context, the type of phase-shifting or time-shifting that causes a current cycle to “lead” the voltage cycle is the opposite of what happens when inductance causes a current cycle to “lag behind” a voltage cycle.

Since capacitance shifts a cyclic current response in a leading direction (i.e., a current peak occurs slightly before a voltage peak, in time), while inductance shifts the cyclic current response in a lagging direction (i.e., the current peak occurs after the voltage peak), those two effects can be balanced out against each other, and they will cancel out each other. To accomplish that result, any desired quantity of capacitance can be added to a circuit, merely by inserting a “capacitor” (a straightforward class of electronic components that can be purchased in a wide range of sizes) into a circuit, at a suitable location, so that the leading effect created by the capacitor will offset (or neutralize, balance out, etc.) the lagging effects that otherwise are created by any coils that create inductance in the circuit.

Accordingly, if an AC circuit which has some level of inductance is provided with the proper amount of capacitance to create a condition referred to herein as L/C balance, this means that the circuit has a current response that is aligned and synchronized with its voltage input (which will be regular and cyclical, in an AC circuit). In this circuit, the alternating voltage cycle, and the alternating current response, will be “in phase”.

Furthermore, as mentioned above, power is calculated by multiplying voltage times current. In an AC circuit, this type of multiplication must take into account the timing and synchronization of the voltage, and the current. If those two different wave forms (the voltage input, and the current response) are properly aligned, in an AC circuit that has a good L/C balance, then the power factor of that AC circuit will be optimized. By contrast, if the current and voltage cycles are out-of-alignment, and out-of-phase, its power factor will be hindered, reduced, and damaged.

Stated in alternate but consistent terms, if an AC system is operating with an L/C balance, the inductive impedance is offset (or neutralized, cancelled, balanced, etc.) by the capacitive impedance. When those two types of impedance are properly balanced against each other, the total impedance (which translates into “hindrance”) of the circuit drops to its lowest possible level. That lowest possible level of impedance is often called “ohmic impedance”, since this type of “pure” or “residual” resistance is measured and expressed in ohms). When inductance and capacitance cancel out each other, and only a residual “ohmic” resistance remains, an electric circuit or device can work at its most efficient level.

Capacitance (and capacitor components) are created by placing conductive surfaces (such as plates, leaves, coils, etc.) close to each other, in a way that enables the positive charges on one metal surface to attract, “stabilize”, and balance out the corresponding negative charges on a nearby metal surface. The capacitance level of a device such as a capacitor is usually measured and expressed in “farads” (derived from the name of the scientist Michael Faraday), or multiples or fractions of farads, such as millifarads (mf). However, the type of capacitance measured in “farads” normally uses direct current, and indicate what is effectively an unchanging “temporary charge-holding capacity” of a capacitor.

By contrast, capacitance in an AC circuit is not a constant value that can be measured once, and then treated as a constant. Instead, capacitance in an AC circuit will usually drop, as the operating frequency increases. Therefore, that type of “dynamic capacitance” is referred to by a variable, which is C.

That completes an introduction to the two different types of electrical and electromagnetic resonance.

The Applicant herein is not aware of any prior devices that combine both types of resonant behavior (i.e., standing-wave resonance, and L/C balance resonance) into a single circuit element. Although various types of devices (such as radio and television receivers) have both (i) a tuning device which uses quarter-wave resonance, and (ii) an amplifier circuit that uses L/C resonance, to the best of the Applicant's knowledge, no one has ever previously created or identified any electrical components that deliberately create and utilize both types of resonance simultaneously, with the possible exception of components that may exist in extremely large “particle accelerators” (also called “atom smashers”) that cost billions of dollars to build.

However, as described below, it is believed that BOTH of those two different types of resonance can be created, and used to good advantage, in certain types of components, exemplified by the types of spiral coils described herein. Because of how these types of spiral coils operate, it is believed that they can create exceptionally powerful electromagnetic fields.

While it is not yet known for certain (and there are reasons for doubting that this result would occur), it may be that, if two coils are positioned and oriented in a “reinforcing” direction, they may be able to create a very strong electromagnetic field that will drive positively-charged particles in one direction, while driving negatively-charged particles in the opposite direction. If that effect occurs, then such “twin coil” devices could be useful in certain types of machines and systems, such as cathode ray tubes, television receivers, vacuum tubes, medical diagnostic devices, and other types of imaging systems, and in various types of chemical manufacturing, biological research, pharmaceutical purification, and other chemistry-related fields of science. While this possibility should be tested, it appears likely that, because of how a “standing wave” is vertically symmetric, if a spiral coil is flipped over, it may simply have the same effect as in the opposite orientation, unless other modifying components are somehow incorporated into the system.

Accordingly, the primary current focus of the invention herein is to disclose that when two spiral coil discs are positioned close to each other, with their dominant planes parallel, they will generate what will be, in effect, a zone with an effect that can be described as “electromagnetic pressure”. Furthermore, because of certain additional factors (including the fact that the “strands” on the outside of a spiral coil are necessarily longer than the “strands” on the inside), it is believed that the type of “electromagnetic pressure” that will be generated by a matched pair of spiral coils, positioned parallel to each other and with a fixed gap between them, will be able to “herd” and “drive” ions or other charged particles into a “center node” that sits between the exact centers of the two coils. Accordingly, that effect can be used to create relatively high concentrations of similarly-charged particles that otherwise would repel each other, in the “center node” of a reactor that is formed by two parallel spiral discs.

Because of the power and importance of resonance in electric devices, this type of “electromagnetic pressure” may be able to operate at any of three levels of increasingly higher power.

At the lowest power level, various types of conventional chemical reactions and biological purifications involve ions, which are called cations when positively charged, or anions when negatively charged. Both types of ions are released by acids, alkalis, salts, and various other chemicals. Accordingly, if ions can be “herded” and “driven” into zones of relatively high concentration, such as at the center of a spiral disc reactor, reactions involving those types of charged particles might be accelerated or otherwise enhanced, even at low temperatures.

The next higher level of power involves a gaseous matter called “plasma” (which must not be confused with blood plasma). When gases are heated (or otherwise treated very to a point where large numbers of electrons are stripped off of the nuclei to which they normally belong, the resulting matter is called a “plasma”. Plasma generators are commercially available, from companies such as Hotek Technologies Inc. (hotektech.com), MKS Instruments (mksinst.com). and Kurt J. Lesker Company (lesker.com), typically at costs of several thousand dollars each. Some of these types of plasma discharge units are used to create extremely hot gases that can be used to weld, etch, or clean metals; other can be used to vaporize metals, for purposes such as atomic analysis, or a coating process called “sputter coating”.

At the most extreme power levels, if the spiral discs disclosed herein are increased in both size and power to sufficient levels, it appears that they can generate electromagnetic fields that will be strong enough to sustain the fusion of hydrogen into helium, in ways that have never yet been accomplished by so-called “tokamak” reactors. Fusion research involving tokamak reactors has now been going on continuously for more than 50 years, and it has consumed countless billions of dollars in research funds, from governments (and therefore taxpayers) around the world. However, more than 50 years of research on tokamak reactors still has never created even a single instance of net power output, where the amount of energy released by hydrogen-to-helium fusion, in a tokamak reactor, was greater than the amount of energy required to conduct that test.

That is a tragic result, because of the extraordinary promise and potential of fusion reactors, if they could only be created. If they can be created, then fusion reactors could generate very large quantities of electric power, with two crucially important advantages. First, a fusion reactor would not require, create, or involve uranium, plutonium, or any other “heavy elements” of a type that create toxic and dangerous radioactive wastes, and that also create fears and threats of uncontrolled nuclear weapons, “dirty bombs”, accidental releases, etc. Second, unlike the burning of oil, gas, or coal, fusion power would not release any carbon dioxide or other “greenhouse gases” into the atmosphere.

Although success cannot be assured, the spiral disc reactor design disclosed herein merits very serious consideration and careful testing, to determine whether such discs (in very large sizes, and run at very high power levels) will be able to create and sustain hydrogen-to-helium fusion reactions that will create net power output. Therefore, a brief overview of the art in the field of fusion research, and tokamak reactors, is provided in the next section.

Fusion Reactions and Tokamak Reactors

As used herein, “fusion reactor” refers to a nuclear reactor that fuses light atoms, into heavier elements. For various reasons that arise from the laws of physics, hydrogen (and its isotopes, deuterium and tritium, which for convenience are included in the term “hydrogen” as used herein) is the only element that offers a practical hope of generating electrical power, by fusing hydrogen atoms into helium atoms. That is the same fusion reaction used by the sun and all stars, and by hydrogen bombs (also called thermonuclear bombs). When the term fusion reactor is used herein, the term reactor implies that the reaction will proceed in a device that is not a bomb, and that will not explode or be damaged by the reaction.

Because of the potential for using fusion reactors to generate electrical power without involving dangerous compounds such as uranium and plutonium, thousands of highly skilled physicists have tried for decades to find some way to obtain a “net output” of power, from fusion reactors. “Net output” refers to the amount of power output released by a reactor, minus the amount of power input that had to be put into the reactor, in order to start and drive the reaction. However, despite more than 50 years of research (and countless billions of dollars in funding), no one has ever created a fusion reactor that could generate even a modest net output of power.

The most widely-studied design, for fusion reactors, is usually called a “tokamak”, also referred to as a “toroid” (in layman's terms, “a doughnut shape”). The design of tokamak reactors is described and illustrated in a good basic summary article that is readily available on Wikipedia, under the name “tokamak”. That introductory article also lists numerous books and articles that provide extensive additional information on how various geometric designs and operating enhancements evolved and led, over the decades, to the current state of the art. However, it must be realized and emphasized that not even a single one of those designs or attempts has ever created a net output of energy, not even in the largest, most advanced, most sophisticated tokamak reactors ever built.

One of the intractable and insurmountable obstacles that has defied all prior efforts to obtain self-sustaining power-producing fusion reactions can be briefly summarized as follows. As temperatures increase, the velocities of the atoms and molecules in a gas increase; indeed, temperature is a direct measure, and index, of how fast the atoms and molecules in a gas are moving, as they collide with and bounce off of each other. Extremely high temperatures (measured and expressed as millions of degrees) are required, in order to put hydrogen gas into a type of “plasma” state or condition where the hydrogen atoms will begin to approach the energy levels they need, in order to fuse with each other when they collide. In this context, the term “plasma” indicates that the hydrogen's electrons are subjected to such high velocities and extreme energy levels that they completely separate from the nuclei of the hydrogen atoms. This creates a dissociated and completely ionized form of the hydrogen gas, with negatively-charged electrons moving at tremendously high speed through the plasma, and with positively-charged nuclei also moving at tremendously high speed through the plasma.

As known to physicists, a conventional hydrogen nucleus is a single proton, with a single positive charge, and no neutrons. In the heavier isotope deuterium (written as 2H), a neutron (with a mass equal to 1, but no charge) has become bonded to the proton. That gives the nucleus of a deuterium atom double the mass and weight of normal hydrogen, but it still has a single positive charge. In the still-heavier isotope tritium (written as 3H), two neutrons have become bonded to the proton, giving the nucleus a molecular weight of three, still with a single positive charge. Since the momentum, inertia, and kinetic energy of any nucleus that is traveling at extremely high speed will increase as mass increases, the nuclei of the heavier deuterium and tritium isotopes of hydrogen will be able to sustain energy levels that render them much more likely to undergo nuclear fusion, when they collide with each other, compared to the lighter nuclei of ordinary hydrogen (1H). Therefore, any serious effort to create and sustain a fusion reaction will use a hydrogen gas preparation that has been enriched and/or semi-purified to contain a high level of the heavier deuterium and/or tritium isotopes.

Returning to the crucial physical barrier that has thwarted and stymied all research efforts throughout history to create net-power-out fusion reactions, extremely high temperature levels in a fusion reactor lead directly to the problem of low density levels, for the high-speed nuclei inside the reactor. Density and temperature are the two main factors that determine the pressure of a gas or plasma, inside a container. Therefore, for any maximum pressure that can be sustained inside a tokamak reactor, during a fusion test, if the temperatures are driven up to extremely high levels (such as in excess of a million degrees), the density will drop off sharply. That density drop has completely stymied any sustained fusion reactions, in tokamak reactors.

This problem, in turn, arises from the fact that no material that can ever possibly be created will be able to withstand temperatures in excess of a million degrees. The strongest alloys ever created, the strongest ceramics ever created, and even diamonds (or any other solid material) will simply melt and then vaporize, if they even begin to approach temperatures such as a million degrees. The bonds that hold atoms together in metal alloys, ceramics, or even diamonds, will not and cannot withstand temperatures of a million degrees. Therefore, a hydrogen plasma, inside a tokamak reactor, cannot be touched or even approached by any type of solid material. As a result, it can only be held in place by an intensely strong electromagnetic field.

Therefore, a tokamak reactor is a complex machine that tries to create an electromagnetic field which has sufficient intensity and power to create a fusion reaction between extremely high-energy, extremely high-velocity nuclei, which are released when all the electrons are stripped away from the heavy isotopes of hydrogen. However, because of the inherent limitations of the design of tokamak reactors, no tokamak reactor has ever succeeded in actually creating a “net power out” fusion reaction. The Applicant herein is convinced that, no matter how much more tinkering and tweaking is done to the design of tokamak reactors, no tokamak reactor will ever be able to “cross the hump” and supply “net output” power to an electric power grid.

Briefly, a fundamental problem that occurs in all tokamak reactors is that they try to compress extremely hot, extremely fast-moving, positively-charged nuclei into a very narrow “pinched” zone that circles all the way around an endless ring, near the center of the “open tunnel” that is created by the doughnut-shaped containment system. Even when steps are taken to try to create “wrinkles” and other discontinuities in the intense electromagnetic fields inside the circular tunnel, the fact remains that all of the particles continue to race, generally in the same direction, around and around, inside the endless tunnel. Even though the electromagnetic fields that are being applied around the entire periphery of the circular tunnel are doing their best to keep those hydrogen nuclei in the super-intense, super-concentrated “pinch zone” near the center of the tunnel, the heat and energy levels that arise inside that tunnel give those particles extreme, intense, and powerful motivation to veer out of (and away from) the super-intense, super-concentrated zone.

Furthermore, the nuclei of all hydrogen, deuterium, or tritium atoms have positive charges, and as a direct result, they will actively and aggressively be trying to repel each other, and resisting any effort or force that tries to “herd” them together into a high-density zone. As the density of the hydrogen nuclei increases to higher and higher levels, the repulsive forces between those nuclei, in the highest-density zone, also increases to higher and higher levels.

As a result, despite the best efforts of thousands of truly skilled scientists to design and create various types of “patches” and “wrinkles” that can create short-lived focal modifications to the electromagnetic fields inside an open ring-shaped tunnel, there appears to be no way that a never-ending ring-shaped tunnel can overcome the inherent problems and “escape paths” that are unavoidably created by that geometric shape.

Accordingly, a spiral-shaped reactor design is believed to offer an inherently better design. The very nature of the design is that it can herd charged particles to the center of the spiral, and once those particles reach the center node, the shape, structure, and geometry of the spiral discs that surround and enclose them will keep them there, even though still more charged particles continue to arrive, leading to increasing levels of higher and higher particle density, in the center node.

It also should be noted that this type of design is consistent with, and emulates in various ways, a number of types of spirals that occur in nature, including spiral galaxies, hurricanes, and numerous types of vortices.

Although this type of reactor design, using a pair of spiral coils positioned near each other to create a “reactor zone” between them, offers better potential than any tokamak reactor, or other reactor design currently known, for being able to create and sustain the hyper-extreme reaction conditions that will be required to run hydrogen-to-helium nuclear fusion on a continuous “net power out” level, the utility and patentability of this design does not depend on whether it can or cannot create and then sustain nuclear fusion. Instead, as mentioned above, other types of useful chemical reactions (including various types of ionic reactions) can be carried out by this type of processing system. Accordingly, such other reactions are sufficient to establish and support the patentable utility of this reactor design, and research involving such other uses will help indicate whether this reactor design can then be extended to the much more extreme conditions required for nuclear fusion.

Furthermore, it must be noted that a single spiral coil, acting by itself rather than as one of a pair of coils, will be able to create more intense and powerful electromagnetic “standing waves” than any other known type of electrical element, if the coil is designed and suited as described herein to simultaneously create and exploit not just one but two different and compatible types of electrical resonance, when operated at a single resonant frequency. Since even relatively small and compact coils of this nature can emit extremely powerful electromagnetic standing waves or fields, they can be used in any analytical, diagnostic, or other type of equipment or environment where such standing waves or fields can be used productively.

Accordingly, one object of this invention is to disclose a “double-resonant” spiral coil as an electromagnetic component of a larger system, which will operate with two different but simultaneous types of electrical resonance, which involve: (i) quarter-wave resonance, which will create standing electromagnetic waves at a resonant operating frequency; and, (ii) a state of inductive and capacitive balance (“L/C balance”), which will synchronize and align the voltage input cycle and the current response cycle in a radiofrequency circuit, in a manner that reduces impedance within the circuit and creates an increased power factor, increased efficiency, and increased power and work output.

Another object of this invention is to disclose a new and improved design for creating electromagnetic components, devices, and systems, using one or more doubly-resonant spiral discs that can generate localized controllable electromagnetic field densities, with strengths and intensities that have not previously been achievable by prior devices that can be created inexpensively by equipment smaller than an “atom smasher”.

Another object of this invention is to disclose a new and improved design for a reactor or effector device that uses two or more spiral coils, in which the electromagnetic fields from the plurality of spiral coils are aligned in a way that allows the device to deflect or otherwise manipulate electrically-charged particles.

Another object of this invention is to disclose charged-particle reactors that contain and include at least one matched pair of spiral coils that will operate at an single operating frequency that simultaneously creates quarter-wave resonance and L/C-balanced resonance, and which generates electromagnetic fields in a reactor zone located between two proximate spiral coils.

Another object of this invention is to establish a reactor design that holds greater potential than tokamak reactors, for creating nuclear fusion in a manner that will generate net power output.

These and other objects of the invention will become more apparent through the following summary, drawings, and detailed description.

SUMMARY OF THE INVENTION

Electromagnetic components and systems are disclosed herein, which use electrical components that will operate with two different but simultaneous types of “resonant” behavior:

(i) “quarter-wave” resonance, in which the length of a wire, antenna, or similar element is equal to ¼ of the wavelength of a radiofrequency alternating voltage that can be established in the component, in a manner which generates an electromagnetic standing wave that has at least one peak node, and at least one null node; and,

(ii) balanced inductive/capacitive (L/C) resonance, in which the impedances created by inductance and capacitance become balanced, in a way that synchronizes current response with voltage input, leading to in-phase behavior of a radiofrequency circuit with minimal impedance, optimal power factor, optimized operating efficiency, and optimized power and work output.

One type of component that can operate with both forms of resonance is a spiral coil, in which: (i) the operating frequency that will establish a standing wave is determined mainly by the length of the conductor element (such as a wire ribbon) in the coil; and, (ii) the cross-sectional dimensions (i.e, thickness and width) of the conductor and its insulation are optimized, so that the wire ribbon or other conductive element will establish L/C balance at the length and operating frequency which establish standing waves in that particular coil.

By controlling and optimizing the cross-sectional dimensions of wire ribbons, spiral coils of various sizes can be created that will achieve both types of resonance simultaneously, allowing them to operate with exceptionally high efficiency and power output. When two such coils are placed close to each other, the combined electromagnetic field they will create, in a “reactor zone” between them, will be very powerful. If used to herd and drive charged atoms, molecules, or particles inward, toward a center node between the centers of the spiral discs, they can create high densities that can promote various types of chemical and plasma reactions involving charge particles.

BRIEF DESCRIPTION OF THE DRAWINGS

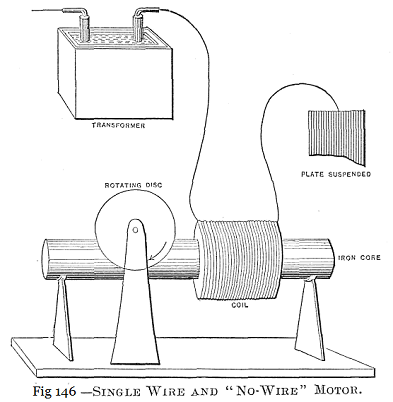

FIGS. 1-4, which are prior art, illustrate the basic principles behind “standing waves”.

FIG. 1 (which includes panels 1A, 1B, and 1C, which are aligned vertically) illustrates what happens when reflected waves (traveling toward the left, in panels 1B and 1C) are superimposed on emitted waves (traveling toward the right, in all three panels), in a wire segment that has a fixed length which is an exact multiple of the wavelength of a radiofrequency voltage that is being pushed into the wire segment by a power supply with a tunable frequency. When the frequency of the RF power supply is adjusted and tuned to the resonant frequency which corresponds to the length of the wire, the combination of emitted and reflected waves creates a “standing wave” condition, which has “peak nodes” and “null nodes”.

FIG. 2 illustrates how the same types of standing waves will occur, if the length of a wire is exactly equal to the wavelength of the radiofrequency voltage being created by the power supply.

FIG. 3 illustrates how the same types of standing wave will occur, if the length of a wire is equal to ½ of the wavelength of a radiofrequency voltage.

FIG. 4 illustrates how the same types of standing waves will occur if the length of a wire is equal to ¼ of the wavelength of the AC voltage. Since a ¼-length wire is the shortest wire length that will create a set of “natural and stable” standing waves, this type of standing wave response is commonly called a “quarter-wave” response. It normally is created, in a wire or other conductor segment having a fixed length, by adjusting and “tuning” the frequency of an RF power supply, until the output frequency corresponds to the length of the wire, in a manner that creates a resonant “standing wave”, which can be detected by various types of instruments.

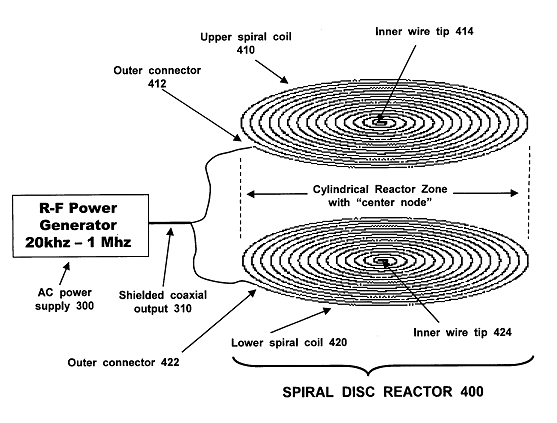

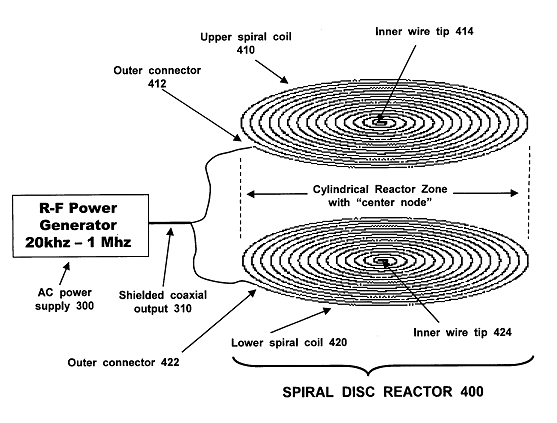

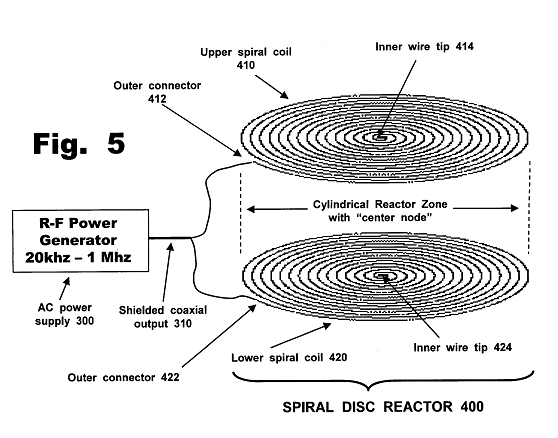

FIG. 5 illustrates a pair of spiral coils and a radiofrequency power supply, which together create a “reactor zone” between the two coils, with standing electromagnetic waves in the reactor zone.

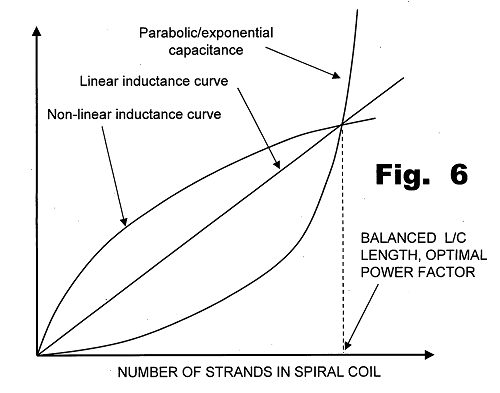

FIG. 6 is a graph, indicating how capacitance and inductance will both increase, as the length of a “wire ribbon” that is used to make a spiral coil increases. Inductance will “jump out to an early lead” in the inner strands, since those inner strands will be coiled fairly tightly. However, after the length of the wire ribbon in the spiral reaches a crossover point, the increase in capacitance, for each additional strand in the spiral, will exceed the increase in inductance. This difference in the shapes and slopes of the capacitance and inductance curves will cause those two curves to cross each other, at some coil length which will depend on the cross-sectional dimensions of the wire ribbon used to make the coil. At that length, the inductive impedance (which causes a current cycle to “lag behind” a voltage cycle) and the capacitive impedance (which has the opposite effect, and which causes the current cycle to “lead” the voltage cycle) will become balanced, and will neutralize each other and cancel out. When that type of L/C balance is achieved within a spiral coil, the voltage and current cycles will become aligned and synchronized; the total impedance of the coil will drop to an “ohmic resistance” minimum; the power factor will reach a maximal level; and the efficiency, power output, and work output of the coil will all increase to maximal levels.

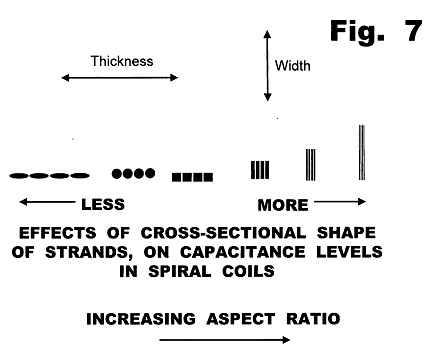

FIG. 7 illustrates how various different cross-sectional shapes and “aspect ratios”, for a wire ribbon having a fixed cross-sectional area, can be used to either increase, or decrease, the capacitance levels in a spiral coil made from such ribbons. This allows the cross-sectional dimensions of a wire ribbon to be optimized, in a manner that will achieve an L/C balance, in a spiral coil which has a fixed length that will determine the resonant “standing wave” operating frequency for that coil.

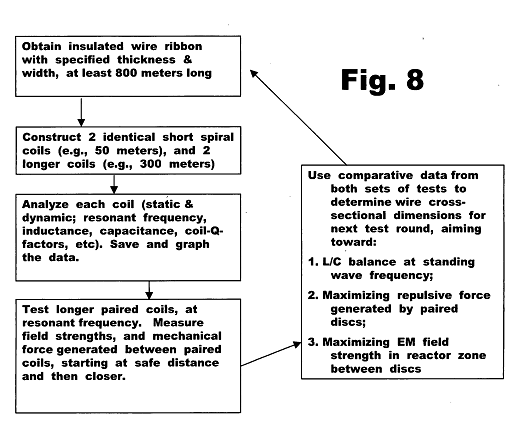

FIG. 8 is a flow chart describing the major steps in an iterative development cycle that enables the cross-sectional dimensions for a wire ribbon to be optimized, in a manner that will enable a spiral coil having a fixed length (and a corresponding operating frequency that establishes an electromagnetic “standing wave” in the coil) to also simultaneously achieve L/C balance at that frequency, which will create an optimal power factor, and maximal power and work output, thereby creating a spiral coil that exploits two different but simultaneous types of electromagnetic resonance, in a manner that creates an exceptionally powerful doubly-resonant electromagnetic standing wave.

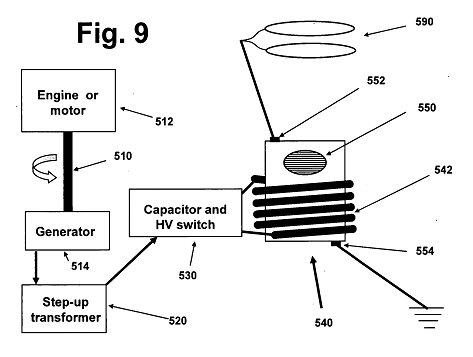

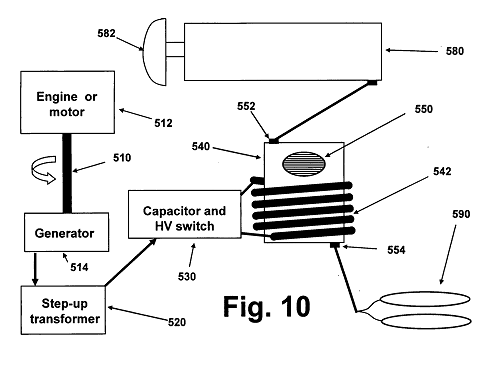

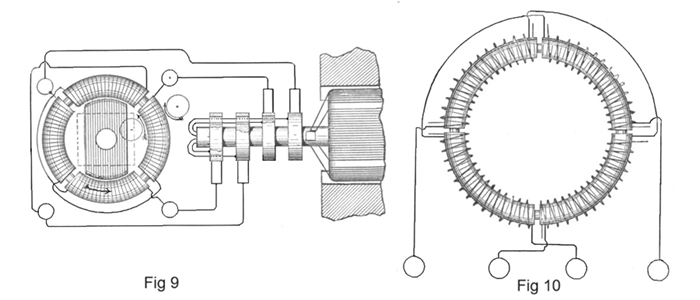

FIG. 9 depicts a reactor formed from two double-resonant spiral coils, coupled to a custom-made power supply of a type that is commonly built by Tesla coil enthusiasts.

FIG. 10 depicts a reactor formed from two double-resonant spiral coils, coupled to a Tesla-type power supply that has been further modified by coupling a resonator unit to the opposing end of the inner coil of the Tesla system.

DETAILED DESCRIPTION

As briefly summarized above, this invention involves spiral coils made of wire (or wire ribbon) having cross-sectional dimensions that have been optimized in a manner that enables a spiral coil to establish and operate with two different but simultaneous types of resonant behavior, referred to herein as:

(i) quarter-wave resonance, in which the length of the wire segment that was used to make the spiral coil is equal to ¼ of the wavelength of an alternating current voltage input, which in most devices of this nature will operate in a frequency somewhere between 10 kHz and 2 MHz, which is conventionally referred to as a “radiofrequency” (RF) voltage range. This type of AC (RF) voltage input can be conveniently provided by adjustable power supply units that can be “tuned” until the output frequency establishes a resonant “standing wave” in the coil.

(ii) inductive/capacitive resonance, also referred to herein as L/C balance or similar terms, which occurs when inductive impedance (which causes a current cycle to lag behind the voltage cycle) and capacitive impedance (which causes a current cycle to lead the voltage cycle) become balanced and cancel out each other, thereby leading to synchronized, aligned, and in-phase current and voltage cycles, which in turn provides an optimal power factor, maximal operating efficiency, and maximal power and work output.

In order to avoid and resolve potential uncertainty over how closely a system should approach a condition of perfect L/C balance, and in order to avoid potential items of unrecognized or unintentional prior art that may be operating in ways that somehow approximate the doubly-resonant devices described herein, the Applicant hereby sets forth two arbitrarily-chosen “benchmark” power factor levels, which are set at 80% and 90% of ideal. If a certain spiral coil has been designed and assembled to a level of quality and performance where its “power factor” is at least 80% of the power factor that could be achieved by perfect synchronization of the voltage and current cycles, then it is deemed to be operating in a state of sufficient L/C balance, and resonance, to be covered by this invention and the claims herein. If its “power factor” is lower than 80%, then it is deemed to not be operating in a state of sufficient L/C balance and resonance to fall within the claims. In addition, the Applicant also hereby sets forth a 90% power factor level, as a preferred benchmark standard that should be met (and preferably surpassed) by any owner or operator that is seriously interested in powerful and optimal performance by devices of this nature.

However, it also must be noted that those arbitrary levels are intended to refer to the potential of an electromechanical system to operate at high power factor levels. In interpreting and enforcing patent claims, the temptation would be extremely powerful for an operating company to create false and misleading test data which fall slightly below any arbitrary level, if and when it knows or believes its performance and output is being analyzed by an entity wishing to enforce patent claims against it; then, as soon as it believes a monitoring session has ended, it can return to improved and optimal operating conditions, while hiding its actions behind agents who will be paid to deny the truth, obfuscate the facts, and mislead anyone attempting to enforce patent rights. Therefore, if a spiral coil system is designed to approach a state of double resonance by using and exploiting the teachings herein, then the ability of an operator to tune and run its system poorly for brief periods, when it is being observed, and then more skillfully and diligently when not being observed, will not remove a properly-designed system that exploits and uses the teachings herein from coverage by the claims below.

Accordingly, when described in terms suited for a patent claim, a device for creating an electromagnetic field is claimed herein, comprising a spiral coil made from a segment of conductive material having a fixed length and cross-sectional shape, wherein:

a. the segment of conductive material is designed and suited to establish a standing electromagnetic field around said spiral coil when one end of the segment of conductive material is excited by an alternating voltage at an operating frequency which corresponds to the fixed length of the segment of conductive material; and,

b. said spiral coil has a wound shape and size which will create inductive-capacitive resonance within said spiral coil, when said spiral coil is excited by the operating frequency which establishes a standing electromagnetic field around said spiral coil.

FIG. 5 depicts a pair of spiral coils that are coupled to an RF power generator. Such power supplies are commercially available from various companies. These types of RF power generators must be distinguished from RF signal generators, which can generate very high frequencies, but only at low power levels. Several brands of RF power generators can provide 1 kilowatt or more of output power, at adjustable frequencies ranging up to 1 MHz, in relatively inexpensive mass-manufactured (“off-the-shelf”) units, and similar RF power units can be custom-fabricated with higher power levels and/or higher frequency ranges.

As mentioned in the Background section, since a voltage wave travels through a wire at about the speed of light, which is about 300 million meters/second, an RF voltage that operates at 1 million cycles/second (i.e., 1 MHz) has a wavelength of about 300 meters. Therefore, the minimum ribbon length for a spiral coil that can generate a “quarter wave” resonant response, to a 1 Mhz frequency, is 75 meters. Because many electrical systems suffer from distortion and other problems when a system operates at the outer limits of its advertised or rated operating range, the minimum length should be increased to at least about 80 meters (which corresponds to a frequency of about 940 khz), and even more preferably to at least about 90 or 100 meters, if an RF power generator is used which is labeled or rated as being able to provide power at a maximum frequency of 1 Mhz.

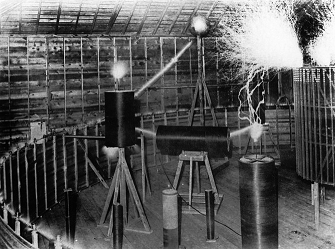

This invention is not limited to commercial RF power generators, for driving spiral coils and/or spiral coil reactors as described herein. In particular, a substantial number of people, ranging from university professors and professional electrical engineers, to “hobbyists”, have developed various ways to build large and powerful RF power generators, to create things like spectacular displays of electrical arcs. An illustrated summary of the components and circuits they use is available in http://en.wikipedia.org/wiki/RLC series circuit, and much more information (including names and contact information for quite a few people who have built and tested these types of circuits, as well as videos showing the results of their work) is available from sites such as teslasociety.com, tesladownunder.com, eskimo.com/˜billb/tesla/tesla.html, the Tesla Coil Mailing List at pupman.com, and a site maintained by the Finnish University & Research Network, www.nic.funet.fi/pub/sci/electrical/tesla/. In addition, at least two companies (Tesla Technology Research, ttr.com, and kVA Effects, teslacoil.com) do this type of work professionally, and offer special effects for movies and television shows, presentations at special events, etc.

Accordingly, the AC power supply 300, shown in FIG. 5 as a box that is labeled “R-F Power Generator”, can indicate either: (i) a commercially-available system, such as a system with a power output of 1 kilowatt or more and with a tunable frequency range up to at least about 1 MHz; or, (ii) a custom-made system, such as described below.

It is believed and asserted that, for a spiral coil having any particular length that will render the coil useful for creating standing waves as described herein, a set of cross-sectional dimensions for a wire ribbon that will be used to make the coil can be identified, by using the methods described herein, that will enable that particular spiral coil to also achieve L/C balance and resonance, at the same operating frequency which will establish a “standing wave” resonant response in that particular coil. Stated in other words, by using an iterative development process that is described herein, a combination of a suitable length, and suitable cross-sectional dimensions, can be identified, which will be used to manufacture wire ribbons that can be wound into spiral coils, which will then establish and utilize two different but simultaneous types of electrical resonance, to create double-resonant spiral coils that will generate exceptionally powerful electromagnetic fields.

Double-Resonant Spiral Coils and Coil Reactors

As illustrated in FIG. 5, reactor assembly 400 comprises two main components, referred to interchangeably herein as discs, coils, spiral coils, or spirals 410 and 420. They will be positioned apart from each other, with their dominant planes parallel to each other, and with a controllable spacing (or gap, distance, spread, etc.) between them. For convenience, it is presumed that both discs will be oriented horizontally, creating an unambiguous configuration having an upper disc (designated as 410 in FIG. 5), and a lower disc (designated as 420). As with tokamak reactors, horizontal orientation will be preferred for most types of chemical or nuclear reactions, since horizontal orientation can neutralize or at least minimize any unwanted variations that might be caused by gravity, density differentials, etc.