Westinghouse Work at the Fair

The Electrical Engineer, August 16, 1893, Vol. XVI

WESTINGHOUSE WORK AT THE FAIR

Our readers will recall, in The Electrical Engineer of April 26, a description of the Westinghouse Machinery Hall services plant from which so large a part of the grounds and buildings are lighted, and which is capable of supplying 189,600 16-c.p. lamps.

At the time the article referred to was written, the plant was just being put in and was in a very backwards condition. It will not, then, be amiss, now that it is complete, and nearly all the generators are in operation, to refer to it once more in connection with a brief review of the company's work at the Fair.

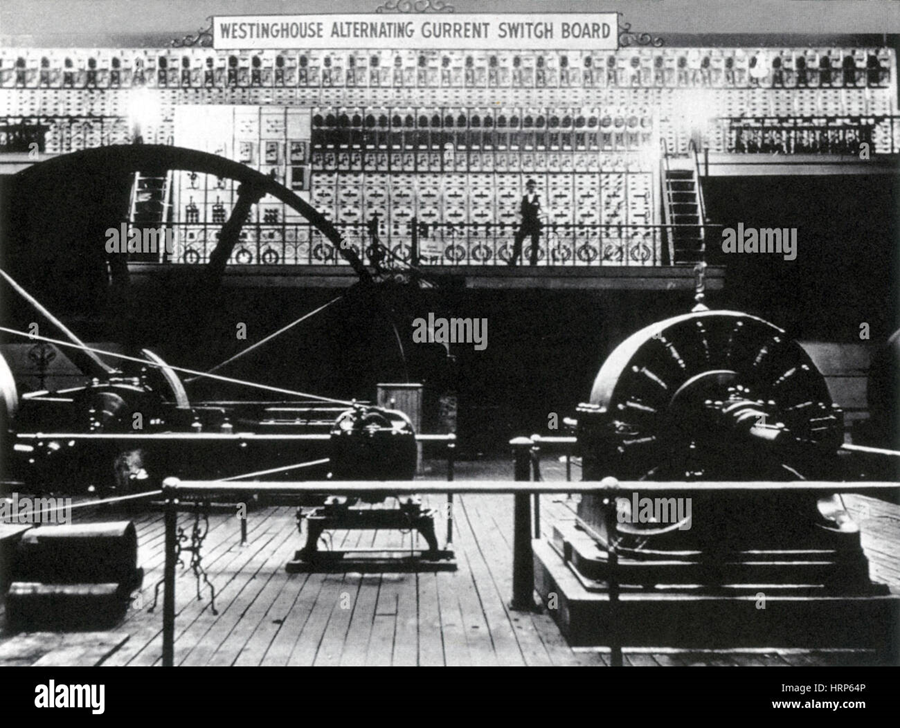

The power plant, occupying the space between columns E, 13 and E, 25 in the south nave of the Machinery Hall, consists of six 750 kilowatt two-phase alternators, two of which are belted to a 3,000 h.p. Allis engine and the other four to 1,000 h.p. engines built by the Fraser & Chalmers, McIntosh & Seymour, Buckeye, and Atlas companies, respectively; six 750 kilowatt two-phase alternators, each directly connected with a 1,000 h.p. Westinghouse Columbian steeple engine; two 240 kilowatt single-phase alternators, each belted to a 350 h.p. Westinghouse compound engine, and three 75 kilowatt exciters directly driven by 100 h.p. Westinghouse compound engines.

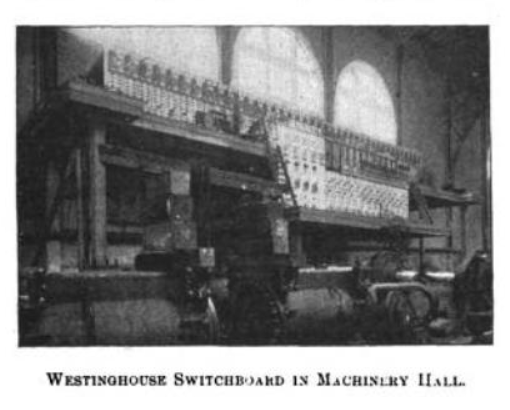

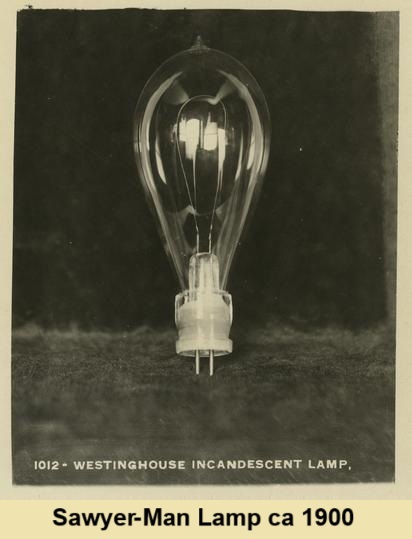

The great white marble switchboard is designed for 12 two-phase and two single-phase alternators, four exciters and 40 circuits and controls nearly all the incandescent and a large number of arc lights in the grounds and buildings including the Midway Plaisance. The switches are so arranged that any one of the 40 circuits can be instantly connected with any of the 14 alternators, and regulating devices are provided for accurately adjusting the candle power of the lamps. All of the incandescent lamps are of the Sawyer-Man stopper type and the arcs are run from Westinghouse constant potential alternating current.

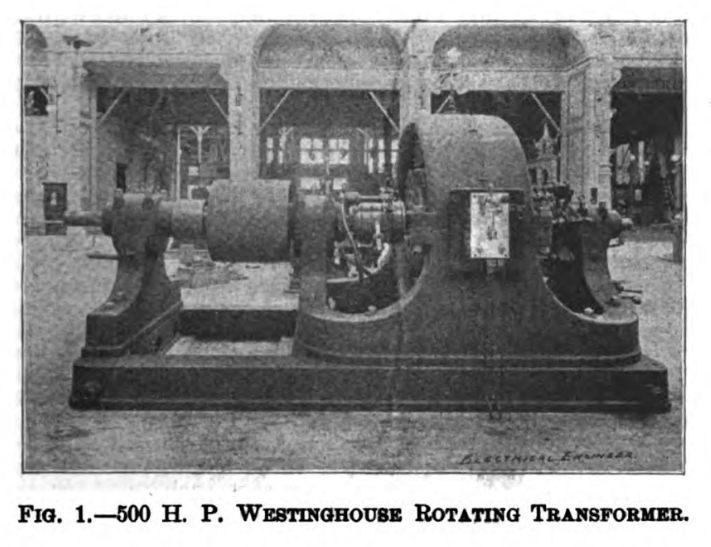

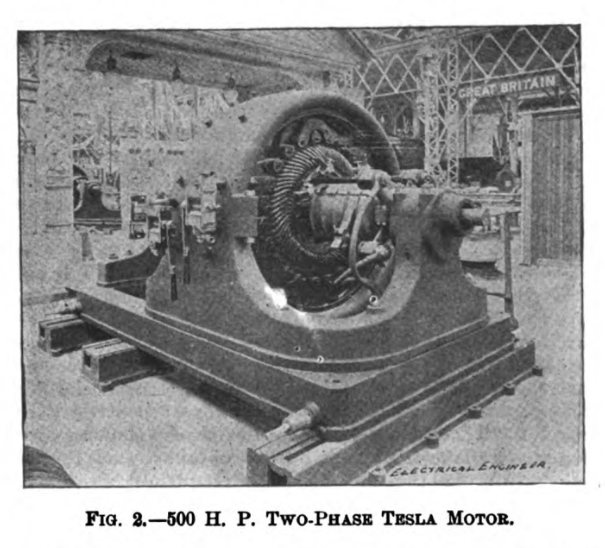

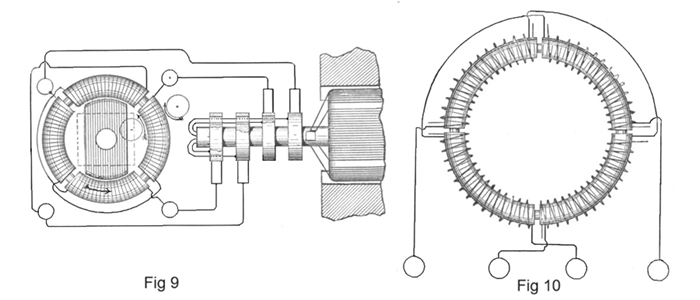

In the Electricity Building the exhibits of the company cover about 15,000 square feet of floor space and while standard Westinghouse alternating current lighting apparatus is fully represented, special attention has been given to recent developments and improvements in the field of applied electricity. In the space marked by the "Golden Pavilion" toward the northern end of the building is a complete power transmission plant using the Tesla polyphase system and touched upon in The Electrical Engineer of June 21, under the title of "Progress in the Electricity Building." It will be remembered that within this one space are shown a generating station, a high tension transmission circuit about 30 feet long and a receiving and distribution station. The first contains a 500 h.p. two-phase alternating current generator, a 5 h.p. direct current exciter, a marble switchboard and the necessary step-up transformers. In practice the generator and exciter would naturally be driven by water power and the former is, in fact, directly belted to a Pelton water wheel, but as water power is not available, instead of the wheel driving the generator the generator drives the wheel, or rather both generator and wheel are driven by a 500 h.p. Tesla polyphase motor with a rotating magnetic field, and the exciter by a 5 h.p. motor of the same type, both operated by current from the large two-phase alternators in Machinery Hall.

ALL EXPOSITION BUILDINGS ARE LIGHTED BY OUR SYSTEM

SEE THE GREAT PLANT IN MACHINERY HALL

The switchboard at the generating station is connected with that at the receiving station by a four-wire overhead circuit. The high tension current is here transformed to 500 volts and distributed to various local circuits. A 500 h.p. two-phase Tesla motor and rotary transformer receives alternating current from the step-down transformer and, exercising its function of motor, drives a Worthington pump and a 40-light Westinghouse alternating current arc light dynamo. As a transformer it delivers direct current at 500 volts to two 30 h.p. railway motors mounted on a standard Dorner & Dutton truck, a 60 h.p. motor driving an Ingersol & Sargent air compressor and several constant potential arc lamps. A 60 h.p. machine of the same type is shown supplied with two-phase alternating current from the reducing transformers. As a transformer it delivers current at 50 volts for electrolytic work, etc.. Beside this is a 60 h.p. two-phase synchronous Tesla motor directly coupled to a 45 killowatt Westinghouse slow speed constant potential alternator for incandescent lighting.

While this system permits the use of exceedingly high tension for transmission over great distances, it delivers both alternating and direct current at any potential at the receiving end of a single circuit from one dynamo at the generating station. In no case is the value of its application more apparent than in mining. Direct current from the rotary transformer is excellently adapted to haulage and hoisting, while the air compressors, lights, etc., may be operated by either the same current or that from the reducing transformers.

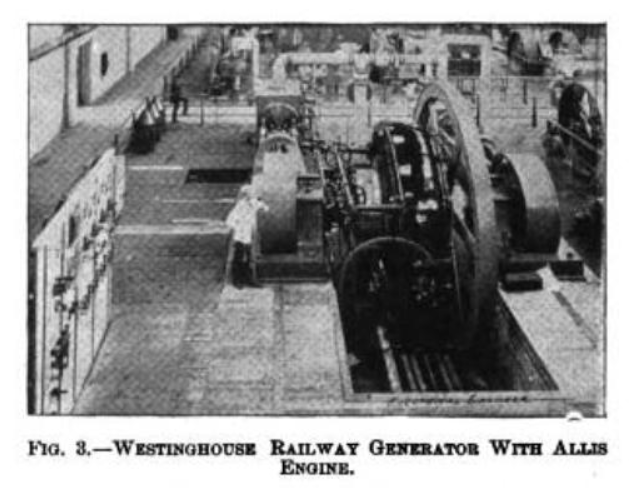

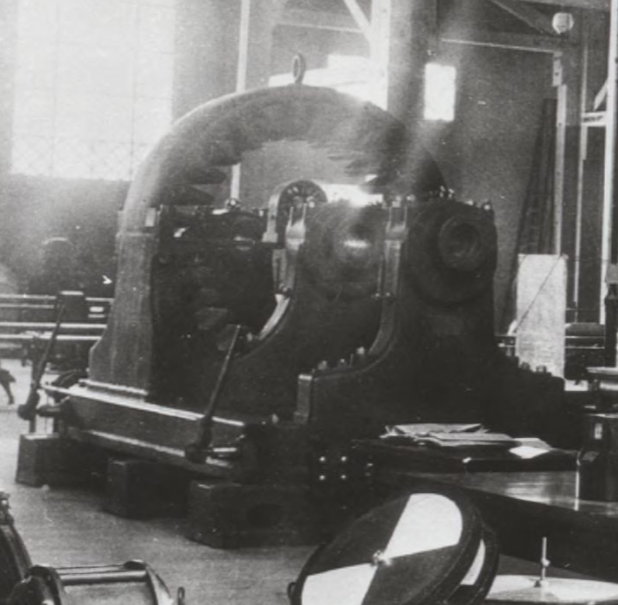

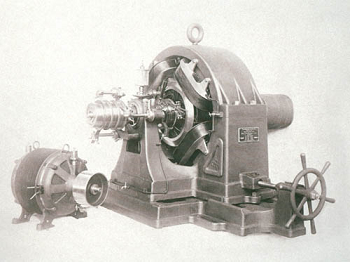

The street railway exhibit in the Electricity Building was fully described and illustrated in The Electrical Engineer, of July 5. In addition to this, however, there are three supplimentary Westinghouse exhibits. Thus, in the transportation building there is a Lamokin 18-foot car with two 30 h.p. Westinghouse single reduction motors and a series multiple controller, etc,; on an exhibition track near the north end of the Terminal Station is a 20-foot Laclede car similarly equipped, and in Machinery Hall has just been completed a 750 h.p. railway generator, the armature of which is mounted directly upon the shaft of an Allis engine running at only 90 revolutions per minute. This machine is unique. It has never before been assembled, as the armature, after being wound, was sent to Milwaukee, where it was fixed to the engine shaft. The illustration, Fig. 3, gives an excellent idea of the peculiar construction and arrangement of the engine and generator. A detailed account of the latter will be forthcoming as soon as it has been run and tested.

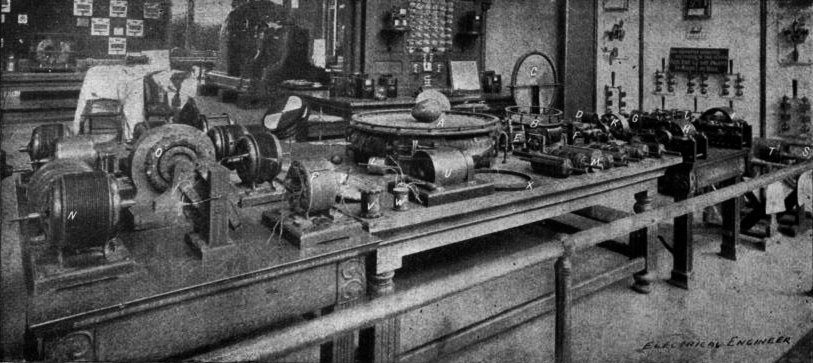

Field from a 500 h.p. machine on display in the Electricity Building directly adjacent to Tesla's personal exhibit. This design was developed from early prototype production line Tesla 2-phase motors in 1888. In the lower right foreground are two of the stroboscopes Tesla displayed. On the lower left is the very top of a Tesla patented motor that he displayed.

Apparatus for arc and incandescent lighting are shown in the Electricity Building just east of the railway exhibit, and include standard alternators of various sizes including the field casting of one of 450 kilowatts, showing the Westinghouse method of casting the laminated poles into the cast iron frame. Here are standard converters and transformers, special converters with non-arcing metal lighting arrestors, direct current motors and generators of the horizontal, multipolar, and Manchester types, alternating current arc light dynamos, Shallenberger meters complete and in operation, and also in parts to show the interior mechanism, Wurts non-arcing metal lightning arresters in operation, other types of arresters for direct currents, and a great variety of well-known styles of switches, ammeters, and voltmeters for direct and alternating currents. In the southwest corner of the space is a dark room for special exhibits of high-potential and high frequency phenomena, where exhibitions are given daily. Some of Mr. Tesla's early apparatus is also shown as well as some of that with which he has obtained such remarkable results in the use of high-frequency alternating currents.

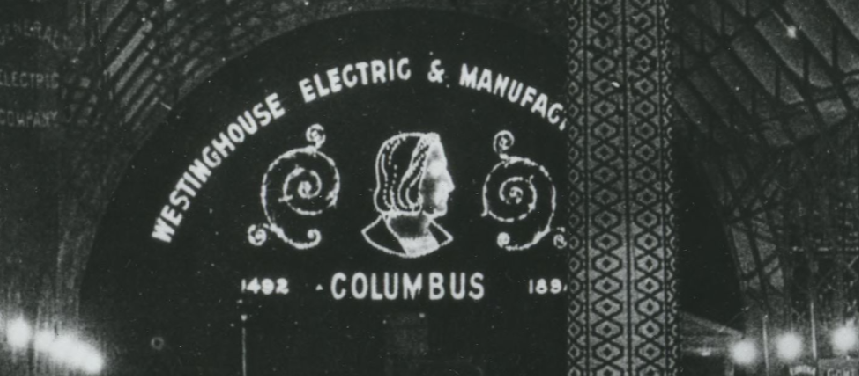

Nearly everyone is now familiar with the great Columbus mural decoration occupying the entire wall space above the south gallery of the Electricty Building and forming a conspicuous part of the Westinghouse display, where the lettering and decorative work is all outlined with Sawyer-Man stopper lamps supplied with current from the central station in the Machinery Hall. The machinery in the Mines and Mining Building, or so much of it as is in operation, is run by two 150 h.p. 500 volt direct current Westinghouse motors, and a 20 h.p. motor of the same make operates an elevator in the New South Wales exhibit in the Transportation Building. The Yale and Towne crane in Machinery Hall, described in our last issue, is also equipped with Westinghouse motors of the Manchester type.

For more on the engines at the 1893 World's Fair I highly recommend:

Steam Engines at the World’s Fair (Parts 1-2)

Also a note on rotary transformers or rotary converters: There are many applications for DC current that are, or were, difficult or impossible to replace with alternating current. In the days before mercury rectifiers and solid state rectification came along, rotational machines were often applied to meet high current demand for DC close to the application. Alternating current could be generated at the power source, like Niagara Falls, then sent as alternating current to a bauxite reducing plant or electric railway, where a rotary converter or "rotary transformer" steps the energy down to a high current DC. The electrolytic reduction of bauxite was so profitable in the 1890's that the Pittsburgh Reduction Company opened three brand new electrolytic reduction plants in Niagara Falls where they could contract cheap electricity from the generators.

By 1891, canals had been dug into the Niagara River above the falls, bringing water to the edge of the gorge from upstream. This water was dropped down the gorge through cast iron pipes to 500 h.p. wheels and generators mounted below. But it would be another five years before the major industrial development was seriously begun, and even that work was superceded by the project planned after WW2 and started operation in 1961.

Related Articles

LIGHTING THE WHITE CITY

The Electrical Engineer - Vol. XV. - April 26, 1893

Mr. Tesla's Personal Exhibit at the World's Fair

Chapter XLII - The Martin Book

The World's Fair in Retrospect

Factory and Industrial Management

The Engineering magazine

Internet Archive Project, 1052 pages with table of contents.

The Inventions, Researches, and Writings of

Nikola Tesla

Thomas Commerford Martin

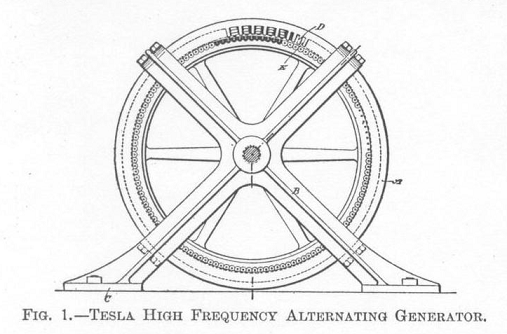

A NEW SYSTEM OF ALTERNATE CURRENT MOTORS AND TRANSFORMERS

Paper by Nikola Tesla read to the American Institute of Electrical Engineers on May 16, 1888

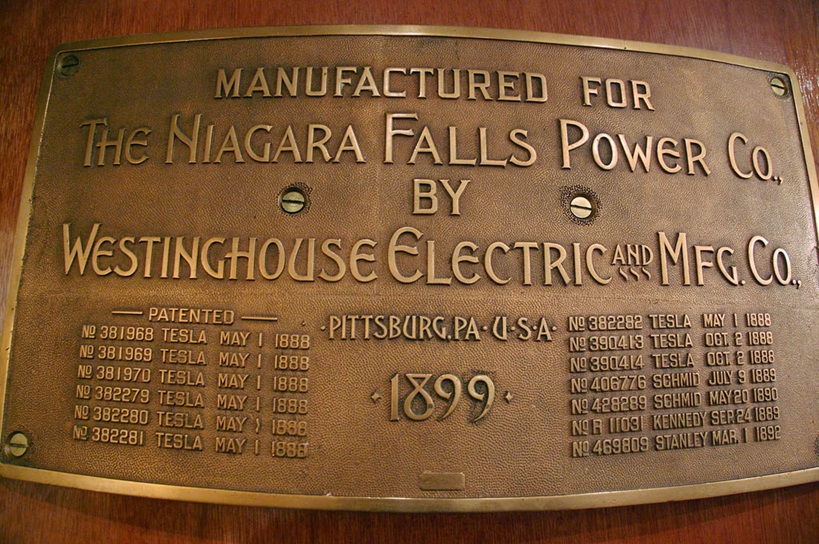

381968 - 381969 - 381970 - 382279 - 382280 - 382281 - 382282 - 390413 - 390414

Articles by Tesla

Tesla made public disclosures of means, methods, systems, and apparatus in various articles.

Tesla's Laboratory Power

Boiler, Steam Engine, Line-Shaft, Belts & Pulleys

To the Archive Page Discussion on Tesla's Technology